Researchers at the Faculty of Mechanical Engineering have developed a groundbreaking method that enables 3D-printed sensors to automatically adapt to temperature variations without the need for additional temperature sensors. The discovery opens the door to broad use of smart structures in variable environments—from aircraft to infrastructure—where existing solutions have not been reliable enough or have been overly complex.

3D-printed piezoresistive sensors allow the detection of deformation, acceleration, and forces directly within smart structures. However, temperature changes can cause up to a 90% change in sensor sensitivity, preventing reliable measurements. Until now, this obstacle has hindered wider adoption of 3D-printed sensor technology.

Conventional approaches require additional temperature sensors, complex calibrations, or special materials. Such solutions increase system complexity, reduce reliability, and make it harder to integrate a larger number of sensing elements.

A study published in the International Journal of Mechanical Sciences (IF = 9.4) reveals that the change in electrical resistance of a piezoresistive sensor is directly proportional to changes in its sensitivity. This makes it possible to accurately predict sensor sensitivity based solely on resistance measurements during normal operation.

A research team from the Faculty of Mechanical Engineering, University of Ljubljana, and the Department of Engineering, University of Perugia, Italy, tested 24 3D-printed accelerometers across a temperature range of 5–35 °C and three humidity levels. Sensitivity predictions within the tested temperature range achieved accuracy better than 5% under normal conditions and 12% under extremely humid conditions. The method requires no additional equipment or sensors, as it relies on a physical property of the sensor that is already monitored during operation. “This approach is an important step forward,” emphasizes Gašper Krivic from the Laboratory for Dynamics of Machines and Structures (LADISK). “Instead of adding complexity, we leverage what the sensor already has.”

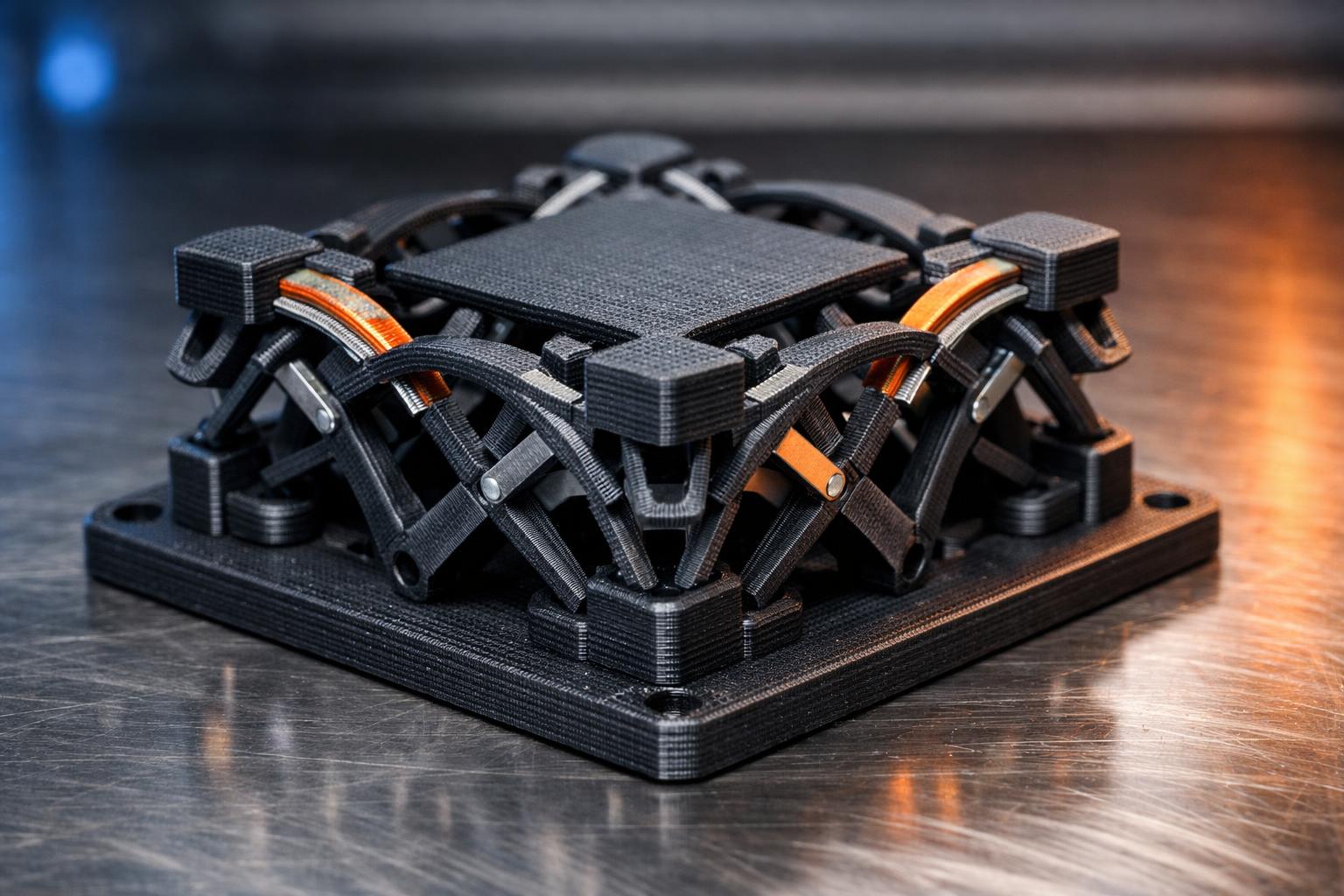

The method enables straightforward integration of multiple piezoresistive sensors into smart structures operating in variable environments. Applications include metamaterials, aerospace systems, and structural health monitoring.