If the student wants to do a traineeship at the Faculty of Mechanical Engineering, University of Ljubljana, he/she must first find a mentor and laboratory where he/she wants to do the traineeship. The student and mentor then make a work programme, which the student adds to the Learning Agreement for Traineeships.

List of Chairs and laboratories

Topics for the traineeships at the selected departments and laboratories

Laboratory for Structure Evaluation LAVEK

Topic: Comparison of conventional and step-stress accelerated fatigue-life testing of composite beams and/or rods (experiments combined with simulations).

Prerequisites: basic knowledge of continuum mechanics, basic knowledge of composites, basic knowldege of using software for 3D modelling and FE simulations.

Laboratory for Hydraulic Machines LVTS

Topics:

1. Aerodynamics and thermodynamics in domestic clothes dryers

2. Measurement of water surface in turbulent flow

Topics:

1. Welding and weldability of materials

2. Bonding of composites and metals

3. Additive Technologies: Wire Arc Additive Manufacturing

Laboratory for Numerical Modelling and Simulation LNMS

Topics:

1. Digital image correlation (DIC) and database set-up for material characterisation

Description: Conventional characterisation of mechanical properties of materials is performed by standardised mechanical testing. However, recent improvements in optical techniques enable the development of modern characterisation methods based on full-field strain measurements, also known as information-rich experiments. A large amount of data is used then to identify model parameters, used in numerical analyses of structures. Activities encompass mechanical testing using the DIC technique and the set-up of database for data processing. Preferred knowledge: programming and computer skills. Info: Laboratory for Numerical Modelling and Simulation.

2. Numerical modelling and FEM analyses

Description: A loaded structure’s thermomechanical response is commonly analysed in a virtual environment. A large variety of mechanical problems can be treated similarly: the behaviour of mechanical parts, a response of tissues in biomechanics, etc. Activities consist of numerical modelling of various mechanical and/or thermal problems and performing Finite Element Analyses (FEA) using the corresponding software. Prerequisites: basic knowledge of Abaqus or Ansys program. Info: Laboratory for Numerical Modelling and Simulation.

Laboratory for Dynamics of Machines and Structures LADISK

Topics:

1. Mentor: prof. dr. Janko Slavič: Python open-source package development in the field of structural dynamics

Prior knowledge: basics of Python programming language, advanced knowledge of structural dynamics and signal processing

2. Mentor: i. prof. dr. Gregor Čepon: Structure health diagnostics using dynamics substructuring and machine learning approaches

Prior knowledge: basics of Python programming language, advanced knowledge of structural dynamics and machine leaning algorithms

3. Mentor: doc. dr. Martin Česnik: Crack propagation and heat generation of 3D printed polymer structures during vibration fatigue

Prior knowledge on: Structural dynamics, Programming (Python), Signal processing, Experimental methods

Laboratory for laser techniques LASTEH

Topics:

1. Laser structuring of metal surfaces

2. Laser structuring of magnetorheological materials

3. Laser generation of ultrasound waves with acousto-optic lens and short laser pulses

4. Laser-assisted 3D printing of biomaterials

5. Development of demonstrator for Fourier optic principles

Laboratory for tribology and interface nanotechnology TINT

Topics:

1. Tribology

2. Nanotechnologies

Laboratory for fluid powers and control (LFT)

Topics:

1. Water hydraulic components and systems

2. Topological optimisation of hydraulic components

3. Technical diagnostics in fluid power

4. Numerical simulations in fluid power

5. Development of didactic systems

6. Digital twins in fluid power

7. High response hydraulic systems, …

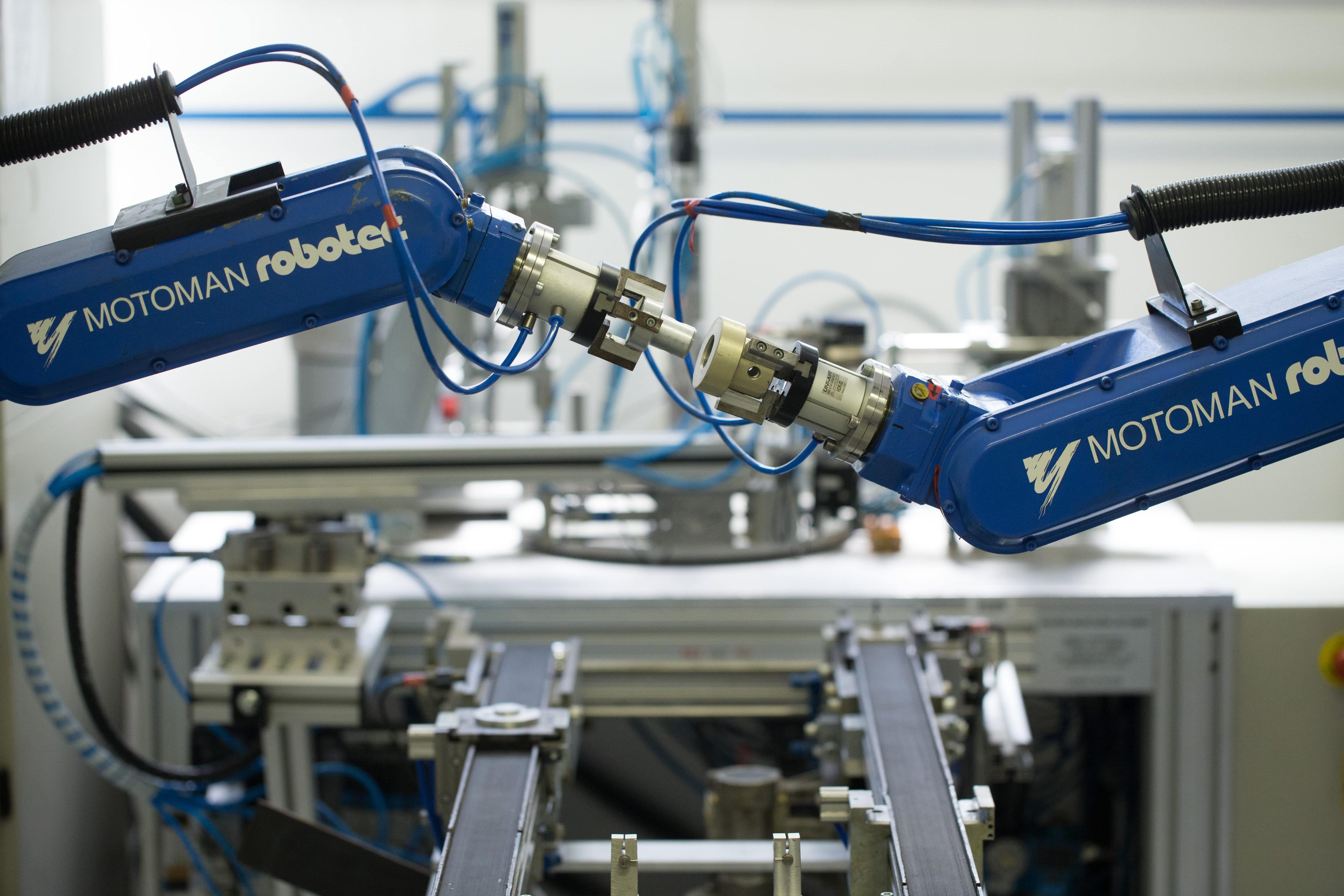

Laboratory of Quality Assurance LAZAK

Topics: Alterative / modern machining processes (milling, turning, drilling) – experiments, performances, optimisation, sustainability in machining processes, CAM, programming of robots, quality for processes and products.

Prerequisites: Basic knowledge of machining processes, machine tools and CAD/CAM.

Laboratory for Engineering Design LECAD

Topics:

1. Heating of temporary plasma limiter in fusion reactor

2. Full blanket thermal model: Stationary cooling of the first wall of the fusion reactor at nominal thermal load

3. ToFu synthetic diagnostic module in SMITER

4. Inverse model of magnetic field of bolometers with machine learning

5. Benchmark TOKES in Lazarus

6. Mapping SMITER on MEMOS-U

7. JOREK Visualization in ParaView

8. JOREK Simplified Model

9. Massively accelerated visualisation of magneto-hydrodynamic simulations

10. Advanced Raysect Models

11. Heat current modelling in tokamak panels by the final volume method (HEAT)

12. Edge-banding plasma modelling in SOLPS-ITER GUI refresh

13. Development of software application for use of AR an VR in product design process

14. Programming of AI based solutions for new product development

Laboratory for Material Handling and Machine Structures LASOK

Topic: Design of special robotic gripper for robotic order picking

Laboratory for Modelling Machine Elements and Structures LAMEK

Topics:

1. Design and analysis of blast response equipment or structures

2. Design and analysis of protective equipment for motorcyclists

3. Design and analysis of roadside protective equipment

4. Injury assessment of humans in dynamic impact scenarios

5. Development and validation of FEM of helmet (bike, motorcycle, ski).

6. Material characterization of HDPE under high strain rates

7. Influence of the curb in the case of vehicle collision into the roadside barrier

8. When is a roadside safety barrier needed to be installed in front of the road sings

9. Numerical model of bone – screw interaction