Researchers from the Laboratory for Laser Techniques (LASTEH) in collaboration with Jozef Stefan Institute (JSI) and the University of Coimbra have experimentally shown that light-to-sound conversion efficiency in a material can be significantly enhanced and controlled. This improvement is achieved by adjusting three key factors: (1) changing of the temporal duration of the laser light used to excite the material, the (2) geometry of the photoacoustic (PA) source, and the (3) nature of the light absorbing material. The combination of picosecond pulsed laser, graphene, and gold nanoparticle decorated graphene in polydimethylsiloxane (PDMS) matrix enables the realization of ultrasound transducers with extraordinary proprieties and a flexible fabrication process. The study therefore aims to enhance the efficiency and spatial targeting of ultrasound-based medical therapies that include macromolecule permeabilization and tumor priming. The results were published in the journal Nano Energy.

The researchers of LASTEH and JSI have developed a two-step protocol that involves dispersing graphene nanoflakes (GR) in PDMS, resulting in a highly absorbent composite on a flexible substrate. Such composite shows a relatively high optical absorption and good homogeneity, even when the thickness is reduced below 10 µm, which represents an advantage for the fabrication of photoacoustic transducers. The use of GR is particularly beneficial due to its stability across various solvents, without the need for special surface preparation and the possibility of in situ decoration of GR with gold nanoparticles (AuNP) without the use of additional reducing agents. The researchers successfully patented the innovative protocol, and the patent was recently granted by the European Patent Office.

“GR/AuNPs/PDMS films are a flexible, scalable, and stable PA source that operates at high laser fluences and peak irradiance of 5 GW cm–2. This approach offers a new solution for the generation of ultrasound waves with higher-frequency components and high peak powers while addressing the fabrication challenges. Moreover, the films obtained with PDMS are very stable and biocompatible. This is crucial for the realization of flexible and minimally invasive tools integrated with conventional medical lasers for biomedical applications aiming at better imaging resolutions, more efficient permeabilization of biological membranes, and photoacoustically assisted medical therapies,” says dr. Daniele Vella.

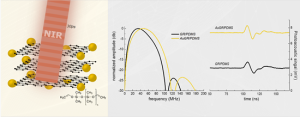

Left: surface decoration of a few layers of graphene intercalated with PDMS and irradiated by a 30-picosecond near-infrared laser. Right: Fourier spectra of the photoacoustic signal from geometrically and optically equivalent polymeric films with and without AuNPs decoration.

The bandwidth of ultrasound waves from nanosecond laser excitation is usually limited by the pulse duration. However, using picosecond laser excitation under stress confinement can produce intense, broadband photoacoustic waves. They observed that the picosecond excitation generates high-frequency PA waves, with bandwidths of -6 dB and -20 dB of around 70 MHz and 130 MHz respectively, and peak pressure > 5 MPa. Additionally, the presence of gold surface decoration leads to a better dispersibility of the GR flake into the polymer matrix and to an increasing bandwidth at -6 dB up to 85 MHz. The reduction in source thickness leads to an increase in ultrasound frequency, which remain stable even when the laser fluence increase up to 150 mJ cm –2. This enables the generation of high pressures while keeping the same bandwidth. The stability of the frequency and amplitude of PA waves over thousands of laser pulses is important in medical therapies guaranteeing the delivery of reproducible PA waves during clinical procedures involving permeabilization of macromolecules and tumor priming.