Researchers from the Laboratory for Forming (LAP) and the Laboratory for Numerical Modelling and Simulations (LNMS) conducted an experimental-numerical study to characterise the through-thickness shear response of anisotropic sheet metal. While the current state-of-the-art approaches for characterising through-thickness shear resistance rely on crystallographic examinations and crystal plasticity models, the novelty of the study lies in the characterisation of the anisotropic out-of-plane shear response based on a macroscopic ball indentation test. The proposed method has been published in one of the leading scientific journals in the field, the International Journal of Mechanical Sciences (IF=6.772).

Conventional methods for describing plastic anisotropy typically rely on advanced yield criteria, which involve conducting multiple in-plane mechanical tests (such as uniaxial and biaxial tests) to calibrate a model. However, in specific forming applications like blanking, ironing, and incremental forming, it becomes crucial to consider the influence of mechanical behavior through the thickness of the material. This necessity prompts the need for characterizing the out-of-plane material behavior. To accomplish such characterization, the utilization of a 3D plastic anisotropy model becomes necessary, with a focus on calibrating the out-of-plane shear parameters. However, determining these parameters can be challenging. Often, researchers make assumptions of isotropy or consider equal shear parameters for both in-plane and out-of-plane behavior. More sophisticated calibrations involve the implementation of crystal plasticity models.

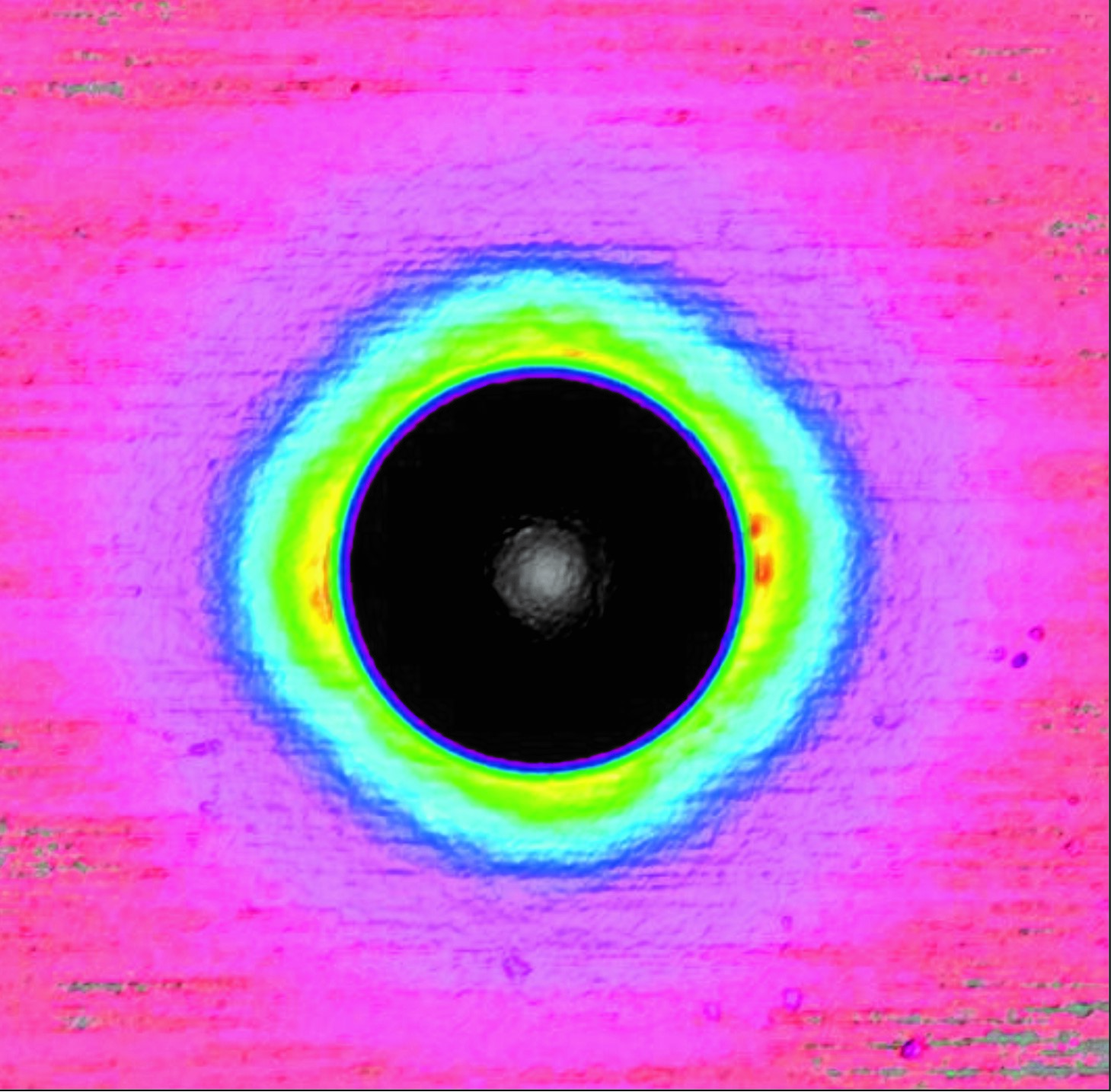

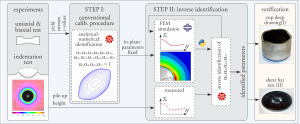

In this study, the authors proposed a two-stage calibration procedure. In the first stage, they conventionally calibrated the in-plane parameters of the YLD2004–18p yield function. Subsequently, in the second stage, after fixing the in-plane parameters, the remaining out-of-plane shear parameters were determined based on the results obtained from the ball indentation test. Notably, this study demonstrated, for the first time, the feasibility of determining out-of-plane shear parameters through a macro-mechanical test on a 2.42 mm thick cold-rolled AA5754-H22 series aluminium sheet.

Link to the article: https://doi.org/10.1016/j.ijmecsci.2023.108403.