Researchers at the Laboratory for Tribology and Interface Nanotechnology (TINT) have investigated the impact of filler combination and scale on the tribological performance in polymer composite/steel contacts under water lubricated condition. This study was conducted in collaboration with the Department of Surface Engineering at Jožef Stefan Institute (Ljubljana, Slovenia) and the Division of Machine Elements at Luleå University of Technology (Luleå, Sweden). The results of the study are published in a recognized journal Tribology International (IF: 6,2).

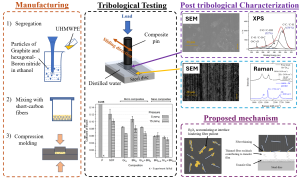

Figure: Image briefly showing the manufacturing method used for the preparation of composites, the arrangement used for tribological testing of manufactured composites against steel, and the post tribological characterization techniques employed for analysis of composite pin and steel disc surfaces.

In the field of polymer-composites, extensive work has been conducted on combining various fillers in the polymer matrix for improvement in tribological performance. However, a notable gap existed in understanding whether the improvement is attributed to the type of filler material or its size, particularly in water-lubricated conditions. The study addressed this lack of understanding by simultaneously examining the impact of filler combinations and their scale on the tribological performance in polymer composite/steel contacts. The combination effect was evaluated by combining various carbonaceous and non-carbonaceous micro-size fillers in Ultra-High Molecular Weight Polyethylene (UHMWPE) matrix. Alternatively, to evaluate the scale effect, one of the fillers was incorporated in combination of micro and nano sizes, while maintaining equal filler concentration in the composition for comparison. Further, the wear mechanisms and the influence of transfer film on the observed friction and wear performance were evaluated in detail by performing SEM, Raman, and XPS analyses.

Amid the risks associated with the spillage and accidental discharge of conventional lubricants, along with the growing emphasis on environmental safety, the focus is now shifting towards more environment friendly alternatives such as water. However, there remains room for improvement in tribological performance where polymer-composite/steel contacts are currently in use with water as a lubricant. This comprehensive study from TINT researchers provides valuable insights into achieving better performance in such applications. Furthermore, the findings from this study are already being utilized by TINT researchers to establish working mechanism of other filler combinations and to create next compositions aimed at achieving even superior tribological performance.