Researchers at the Laboratory for Fluid power and Controls (LFT) and at the Laboratory for Tribology and Surface Nanotechnology (TINT) investigated the tribological properties of selected high-performance polyetheretherketone (PEEK) and commercially available polyoxymethylene (POM) in different glycerol aqueous solutions. The objective was to evaluate the performance of this environmentally adaptable lubricant (EAL) in polymer-steel contacts.

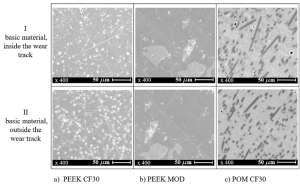

Figure 1. SEM micrographs of composite samples tested in glycerol + 40 % water: I) inside the wear track; II) outside the wear track.

The use of environmentally adaptable lubricants (EALs) is becoming mandatory in maritime shipping and hydroelectric power plants, as well as in forestry and mobile machinery, as ecologically sensitive applications. In this study the potential benefits of using glycerol aqueous solutions containing 20 to 80 % water on the tribological properties of three different polymer composites were analysed: PEEK CF30 (PEEK reinforced with 30% carbon fibre), PEEK MOD (PEEK reinforced with 10 % carbon fibre, 10 % graphite and 10 % polytetrafluoroethylene), and POM CF30 (POM with 30 % carbon fibre).

The results prove that by adjusting the water content in the glycerol-water mixture the lubricant’s viscosity can be lowered to the boundary value, which enables a low, stable and comparable coefficient of friction as well as low and comparable values of the specific wear rate for the tested polymer composites. When there is more than 60 % of water in glycerol-water mixtures delamination of polymer matrix starts, and the transfer film becomes more intense for all the tested polymer composites.

Although there is an obvious change in the wear mechanism when there is a higher water content in the mixture, commercially affordable POM CF30 successfully fallowed high-performance PEEK CF30, showing the lowest coefficient of friction compared to the both PEEK composites tested.

Article is available at: https://doi.org/10.1016/j.triboint.2023.109173