Researchers at Laboratory for Tribology and Interface Nanotechnology (TINT) have carried out an analysis of the evolution of the real contact area during sliding at different loads and surface roughnesses. An in-house developed optical test rig with sub-micrometric lateral resolution was used for the analysis of the asperities, which is the best published in the literature to date. This provided the most accurate real contact area data during sliding, allowing them to compare and validate one of the fundamental friction mechanisms, i.e. Tabor’s model of junction growth. Based on these findings, the TINT laboratory is also already developing new models to determine the friction in dry contacts as a function of the real contact area.

Surface-to-surface contact is important for efficient design and to ensure the longevity of machine elements. Since all real surfaces are rough, the actual contact occurs as the sum of all local micro-contacts between the roughness asperities on the surfaces, i.e. at discrete points between the surfaces, which is known as the real or true contact area. The real contact area is always smaller than the nominal area, which can strongly influence the calculations of contact conditions such as electrical and thermal conductivity, contact pressure, load-carrying capacity, etc. Since the real contact area is ‘hidden’ in the contact, taking place at the scale of only a few micrometres, and is highly dependent on the contact conditions and the properties of the materials and surfaces, it is not easy to measure. This is particularly true when considering contacts with relative motion, such as sliding contacts.

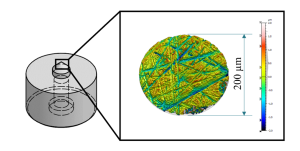

Figure: Schematic representation of a sample for real contact area analysis during sliding.

There are many attempts in the literature to establish a reliable theoretical model to predict the real contact area as an input for contact design. However, there is still not enough detailed experimental evidence of the evolution of the real contact area in multi-asperity contacts during sliding to compare with the models and thus provide validated insight into the actual contact behaviour at the micro-scale, where the asperities carry most of the load in metallic contacts. Knowledge of the real contact area is crucial for successful modelling of both wear and friction, which remains an important challenge in Tribology. With this extensive research, TINT researchers have contributed to new knowledge along this path.

Link to the scientific paper: https://doi.org/10.1016/j.triboint.2023.109171