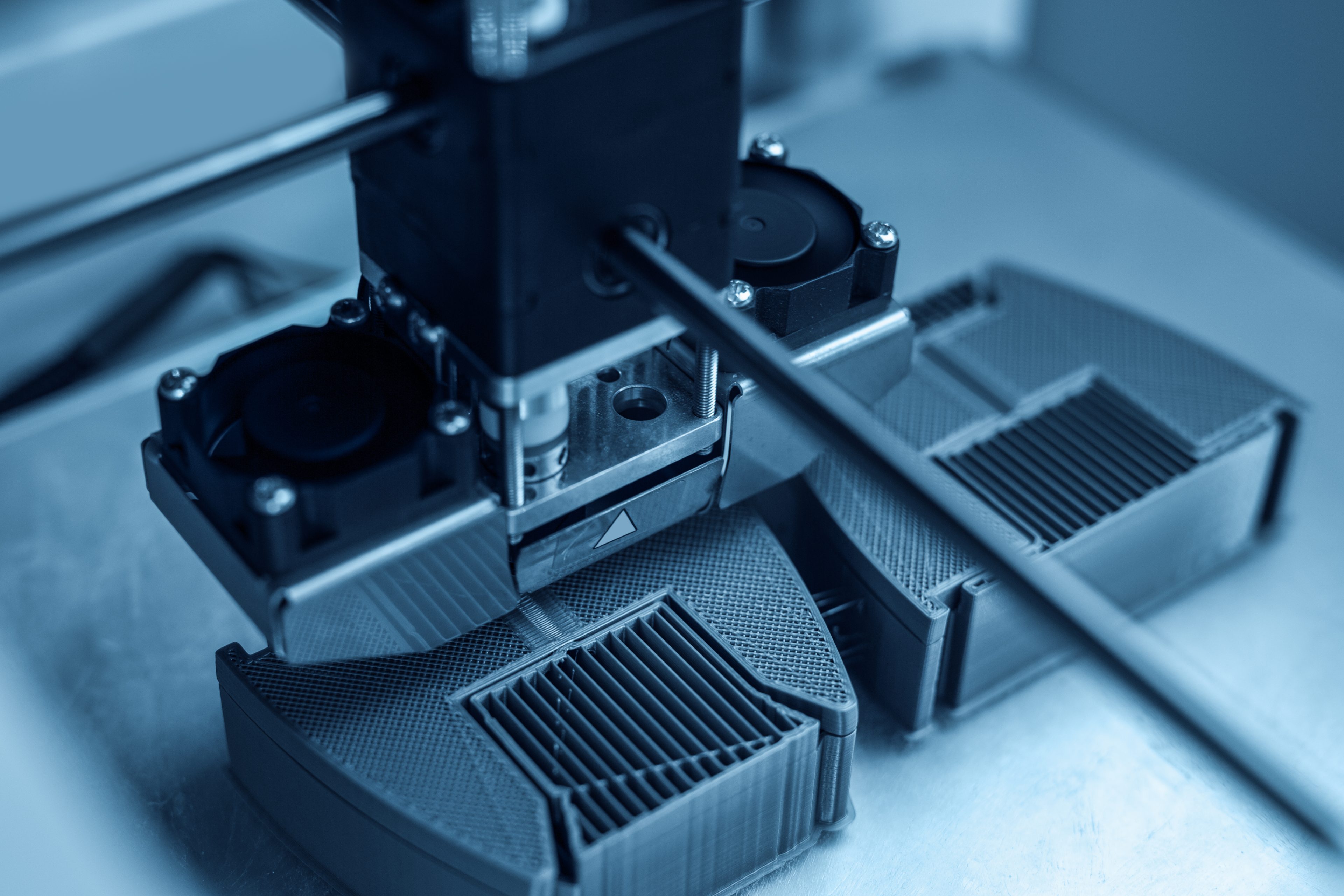

Researchers from the University of Ljubljana’s Faculty of Mechanical Engineering have presented a method for 3D-printing piezoelectric sensors that are immune to electromagnetic interference. Their work has been featured in the leading scientific journal Additive Manufacturing (IF=11.632).

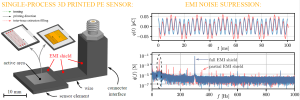

Piezoelectric sensors, vital in industries from robotics to healthcare, transform mechanical energy into electrical signals and vice versa. Their versatility, however, is shadowed by sensitivity to electromagnetic disturbances, which can skew readings. The Ljubljana team harnessed 3D printing, using a blend of piezoelectric, conductive, and standard thermoplastics, to manufacture a high-sensitivity sensor with integrated electromagnetic shielding in one single process.

What sets this research apart is the comprehensive 3D-printing of the piezoelectric sensor – encompassing the connecting wires and interfaces compatible with mainstream measuring equipment. To ensure functionality and full shielding, the researchers introduced techniques like “inter-trace extrusion filling” and “electrode ironing” to sidestep potential electrical pitfalls during manufacturing.

This advanced design seamlessly integrates with commercial connectors and measuring devices, broadening its utility. Experimental evaluations revealed a signal-to-noise ratio of 27 dB, indicating its ability to detect subtle signals with minimal interference.

This transformative approach to sensor fabrication enables applications, from monitoring the health of infrastructure to advancements in robotics and biomedical engineering.

Link to the article: https://doi.org/10.1016/j.addma.2023.103699.