Researchers from the Welding Laboratory (LAVAR), FS-UL, in collaboration with researchers from Arts et Métiers ParisTech (ENSAM, CNRS) and Faculty of Natural Sciences and Engineering UL, have presented an innovative approach to mitigate crucial defects of directed deposition of alloy 5356 with in-situ substrate vibration. The presented methodology was published in the Journal of Materials Research and Technology (IF: 6.2).

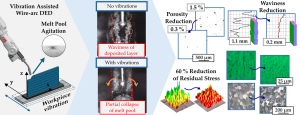

The developed innovative approach reduces the residual stress gradient, improves surface quality, and decreases the level of gas porosity. At the same time, it also enhances the energy efficiency of the process.

The deposition of molten material under the influence of vibrations reduces waviness and improves the final dimensional accuracy. At the same time, vibrations induce mixing and homogenization of the melt pool, which affects the kinetics of crystallization. This leads to a reduction in grain size and the elimination of tensile strength anisotropy. Consequently, the need for subsequent heat treatment is reduced. This methodology presents a promising solution for improving the mechanical properties of DED products and their further practical application.