Most heat exchangers accumulate foulants during operation, which negatively affects operational characteristics and efficiency of heat transfer. Cleaning or replacing degraded heat exchangers induce significant costs which can be reduced by planning the maintenance in advance. Researchers from the Laboratory for Thermal Technology (LTT) developed a method for remaining useful life prediction, with which a new generation of smart heat exchangers will predict the time until maintenance is necessary. The results are published in the journal Applied Thermal Engineering (IF = 6.9).

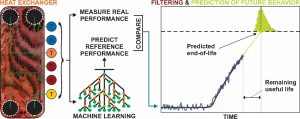

Figure 1: Schematic of remaining useful life prediction of a heat exchanger during operation.

More than 90% of heat exchangers experience some degree of fouling problems. The resulting economic loss is estimated at approximately 0.25% of GDP in developed countries, while the deterioration of operating characteristics in oil refineries alone indirectly causes at least 2.5% of all anthropogenic CO2 emissions.

Despite many successful mitigation strategies, it is impossible to completely prevent fouling, which is why heat exchangers must be cleaned or replaced, causing downtime and high costs. To minimize the latter and avoid long process shutdowns, the field of predictive maintenance is rapidly developing in recent years, relying on prediction of remaining useful life

Recent prediction algorithms rely on large databases of experimental measurements, which are the basis for training advanced models. However, their applicability is limited to the specific fouling problem found in the database, which represents a major obstacle to practical deployment, where fouling dynamics are not known or predictable ahead of time.

The presented research addresses these limitations by developing a new method for predicting the remaining useful life of a heat exchanger, without the need for prior knowledge of degradation. The developed prognostic approach combines: (i) a machine learning model that predicts the reference efficiency, (ii) an adaptive Kalman filter for identifying degradation, and (iii) a Monte Carlo simulation for predicting remaining useful life. The algorithm adapts to fouling dynamics during operation, which allows it to successfully track and predict various degradation trends in heat exchangers.

Given the magnitude of the problems caused by fouling from the perspective of economic and energy-efficient processes, such an adaptive prediction of the remaining useful life represents a great opportunity for developing the next generation of smart heat exchangers.