Friction and wear are important contributors to energy use and component failure in mechanical systems. Reducing friction to superlubricity (µ< 0.01) is a modern strategy to reduce energy use and wear in industrial systems. In a recent study, researchers from the Laboratory of Tribology and Interface Nanotechnology (TINT) have demonstrated that one effective approach to reduce friction and wear is to use graphene quantum dots (GQDs) added to aqueous glycerol. The research was carried out in collaboration with the Institute of Chemistry (Ljubljana, Slovenia), the Jožef Stefan Institute (Ljubljana, Slovenia) and the University of Coimbra (Coimbra, Portugal). The work is published in a journal of Materials & Design (IF=7.6).

Traditional oil-based lubricants, which are most commonly used in industry to reduce friction and wear, contain hazardous elements such as phosphorus, zinc and sulphur, which contribute significantly to environmental pollution. In contrast, apart from biodegradable oils, various polyhydric alcohols, for example, ethanediol, glycerol, 1,3-propylene glycol, and myo-inositol, are gaining attention as green lubricants due to their environmental friendliness and high water solubility. Glycerol is the most widely used, due to its good biocompatibility and cost-effectiveness. Moreover, several tribological studies reported super-low friction in various tribo-systems using polyhydric alcohols. However, in most of these studies, a long running-in period is required to achieve stable, super-low friction, which leads to a mechanical deterioration of the tribo-pairs and, consequently, severe wear.

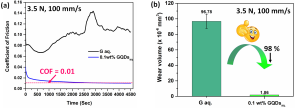

In the study, the researchers highlight the excellent tribological properties of graphene quantum dots (GQDs) as an additive in aqueous glycerol for steel/steel interfaces at high contact pressures. The addition of a small amount (0.1%) of GQD to aqueous glycerol significantly reduces the running-in time and reduces the COF to an average value of 0.012, which is almost equivalent to superlubricity and represents an 88% improvement compared to aqueous glycerol. In addition, the anti-wear performance is improved by 98% (Figure 1), resulting in extremely low friction even at a high contact pressure of 316.5 MPa in the boundary lubrication regime.

Figure 1: Friction and wear reduction ability of GQDs-based nanolubricants; (a) COF versus time curve, (b) variation in the wear volume compared to aqueous glycerol.

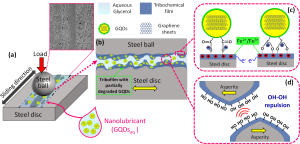

This improvement in tribological performance was attributed in the study to several factors, including shearing of the graphene layers within the GQD, exfoliation of the graphene layers within the GQD, and repulsion of OH-OH groups between the asperities during the break-in phase. In this process, the tribofilm is formed by electrostatic adsorption of the GQDs on the positively charged worn metal surface, while the GQDs in the tribofilm undergo tribo-induced structural degradation, which protects the surface from wear and allows the maintenance of extremely low friction at high contact pressure (see Figure 2).

Figure 2: Proposed lubrication mechanism of the self-mated steel contacts in the boundary-lubrication regime using GQDsaq. (a) Overall representation of tribotest (inset SEM image of the wear track), (b) schematic of the tribochemical film formed on the worn steel surface, (c) adsorption mechanism of the GQDs indicating the anion from the GQDs adsorbed onto the positively charged worn steel surface via electrostatic interaction, facilitating the formation of a robust tribofilm, (d) schematic of the OH–OH repulsion between asperities preventing direct contact.