Researchers from the Laboratory for Dynamics of Machines and Structures at the Faculty of Mechanical Engineering, University of Ljubljana, have presented a method for 3D printing an active metamaterial cell capable of adapting to dynamic loads. Their work has been published in the scientific journal International Journal of Mechanical Sciences (IF=7.1).

Metamaterials are meticulously designed structures with effective material properties that are not typically found in nature. They are composed of basic building blocks or cells that are periodically repeated in the structure. The researchers have developed a metamaterial cell that, with the help of local resonators, can attenuate mechanical vibrations within a narrow frequency range. Locally resonant metamaterials are frequently used in various applications, such as vibration reduction in the aerospace industry and improving sound insulation in construction and the automotive industry.

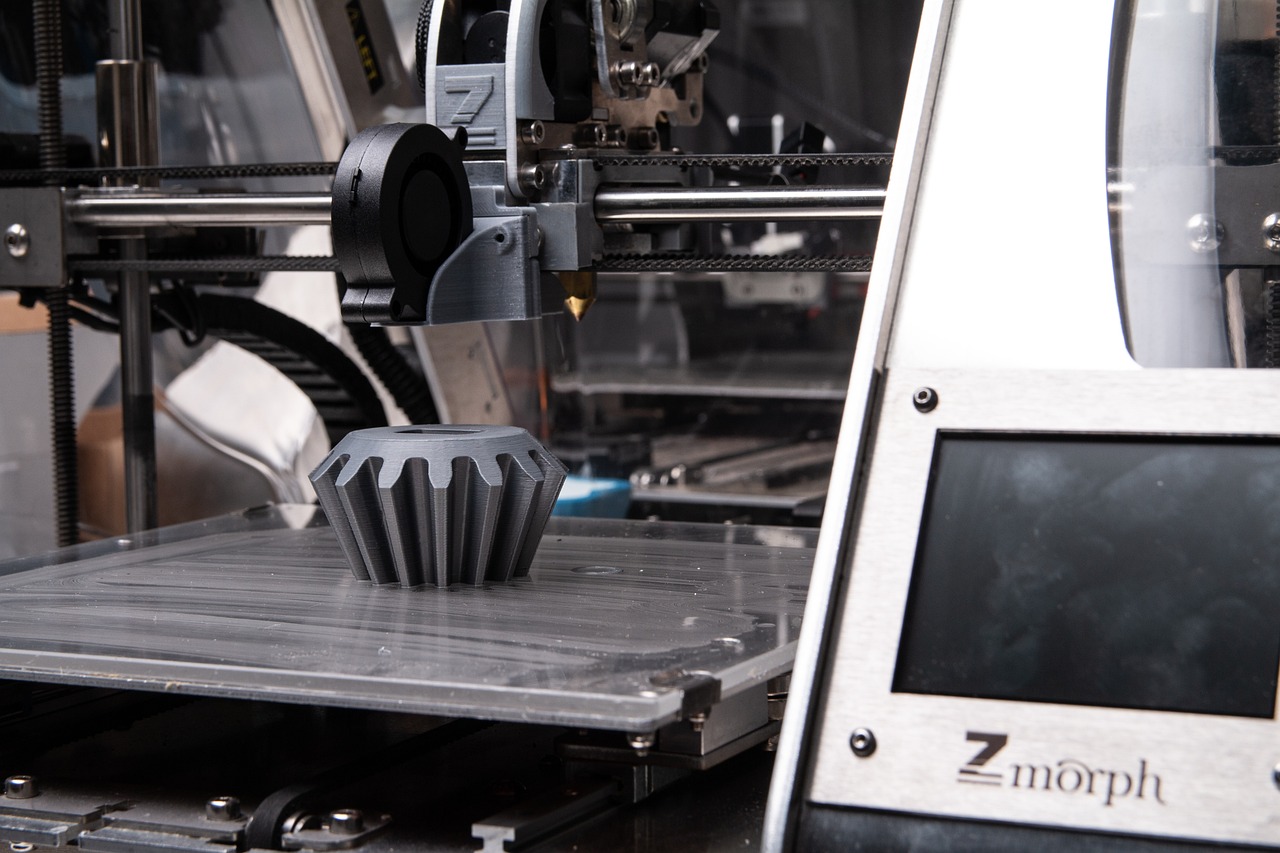

Compared to previous research, the presented metamaterial cell is entirely 3D-printed and also enables load detection, temperature measurement, and the adjustment of the frequency range of vibration attenuation. These features have not previously been combined in a single metamaterial cell.

Researchers are the first to fully print an active metamaterial smart cell (it can sense loads, temperature, and adapt to these conditions) in a single process using thermoplastic extrusion of the material. The cell consists of a base structure and a resonator and also includes 3D-printed conductive paths. By heating these conductive paths with electric current, the stiffness of the resonator changes, which in turn alters the frequency range of vibration attenuation. Temperature is measured through changes in the quasi-static component of the electrical resistance of the conductive paths, while the excitation frequency or load on the metamaterial is detected through changes in the dynamic component of the electrical resistance.

With these functionalities, the metamaterial cell is capable of sensing environmental loads and adapting by altering the frequency range of vibration attenuation. Active metamaterials composed of the presented cells have potential applications in areas where vibration reduction is desired, while the frequency content of mechanical vibrations changes over time.