The article Small demonstrator of a thermoelectric heat-pump booster for an ultra-low-temperature district-heating substation represents, as first in the world, experimental proof which demonstrates the effective use of thermoelectric heat pumps in a 4th or 5th generation district heating systems. The article was published in the journal Applied Energy (IF=11.2).

The investigation was carried out by the researchers of the Laboratory for refrigeration and district energy (Process Engineering) in cooperation with the company Danfoss Trata d.o.o.

One of the most important measures for the energy efficiency of district heating systems is to reduce the supply and return temperatures of the system. The 4th generation district heating systems operate at supply temperatures of 50 to 60 °C, which enables better utilization of renewable and waste heat sources. In the 5th generation, supply/return temperatures are significantly lower (< 30°C). These temperature levels lead to the need for a local increase in the heating temperature (e.g. for the sanitary hot water), which is solved by using auxiliary heat pumps or so-called ˝booster’s˝. Energy-consuming electric heaters or fuel-burning boilers are most often used to raise the temperature, while heat pumps are an alternative. Among the latter, vapor-compression heat pumps are in use, but they use environmentally unfriendly or toxic and flammable refrigerants, are noisy and cause vibrations, which negatively affects the comfort of living in the living environment.

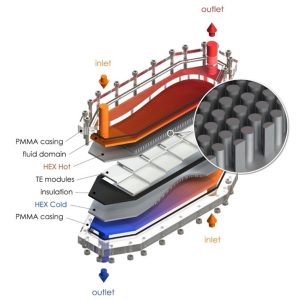

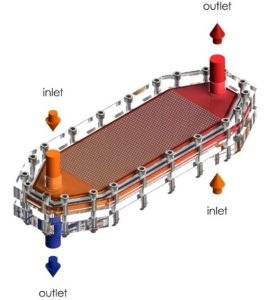

Figure 1: 3D model of TE-HP booster: the exploded (top) and the assembled view (bottom).

In the published research, the researchers present the development and operation of a demonstration thermoelectric (Peltier) heat pump booster (TE-HP), which can serve as an auxiliary heat pump in the substation of the 4th or 5th generation district heating system. An extensive parametric experimental analysis is presented in terms of heating capacities, flow rates, supply water temperature increase and efficiencies.

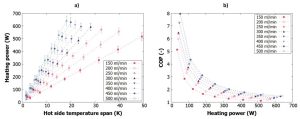

Slika 2: Experimental characterization of TE-HP booster operation: a) heating power vs. hot-side temperature span for different flow rates, b) COPH vs. heating power for different flow rates.

The developed TE-HP demonstrates many advantages over the comparable state-of-the-art, namely extreme compactness, silent operation without moving parts and vibrations, high efficiency of operation and the use of environmentally friendly recyclable refrigerants without discharges into the environment. It operates in the range of heating powers up to 650 W and the highest temperature increase of the supply water up to 50 K. At a temperature increase of the supply water by 10-15 K, it operates with a heating coefficient of performance (COP) between 2 and 2.4, which represents the ratio between the obtained heat and the electrical input energy, which significantly outperforms any direct conversion of fuels or electricity to heat, which has a COP ratio < 1.

Article is available on: https://doi.org/10.1016/j.apenergy.2024.122899