Researchers from the Welding Laboratory (LAVAR), in collaboration with researchers from the Department of Mechanical Engineering, University North, University Center Varaždin in Croatia, have demonstrated through experimental analysis how the chemical composition of active particles affects the ionization potential and penetration depth in A-TIG (Tungsten Inert Gas) welding of electrolytically pure copper. The research results have been published in the Journal of Materials Research and Technology (IF=6,4).

A-TIG welding or TIG welding with active particles is an energy-efficient and sustainable process for joining materials, allowing for greater depth of weld penetration with the same or even lower energy input. In this process, certain metallic oxides, sulphides, fluorides, or chlorides act as activators, influencing the depth of penetration and the quality of the weld joint. Active particles in the welding arc increase the concentration of energy by altering the ionization potential and increasing electron energy. The presence of activators above 50 ppm further modifies the surface tension gradient (dγ/dT), which reverses the direction of the Marangoni melt flow. This altered Marangoni flow positively affects penetration, as the melt travels from the cold edge towards the hot centre of the joint.

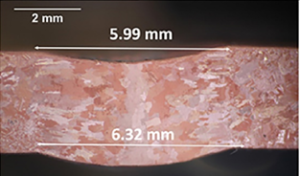

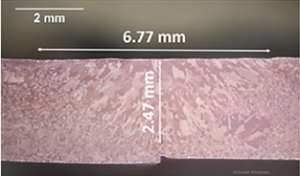

Slika 1: The macrograph of the weld produced by a) TIG welding with a heat input of 4.93 kJ/cm and b) A-TIG welding with 3.17 kJ/cm.

The results of the conducted analyses have confirmed the maximum depth of penetration when using active particles of silicon dioxide (SiO2), which enable complete penetration without porosity, even with a 30% lower energy input compared to conventional TIG welding. Welded joints produced in this way exhibit appropriate bending and tensile strength. Researchers aim to achieve additional energy savings in further research in this field while maintaining the same depth of weld penetration and adequate weld joint strength. This discovery can now be applied in the fields of electromobility, automotive industry, and electrical engineering.