Researchers at the Laboratory for Tribology and Interface Nanotechnology (TINT) investigated the robustness and the durability of the superlubricity in steel contacts provided by the carboxylated graphene quantum dots (CGQDs) as an additive in environmental adaptive lubricant. This work was done in collaboration with the National institute of chemistry, Jožef Stefan Institute and the University of Maribor. The results of the research were published in the journal: Carbon (IF=10.5)

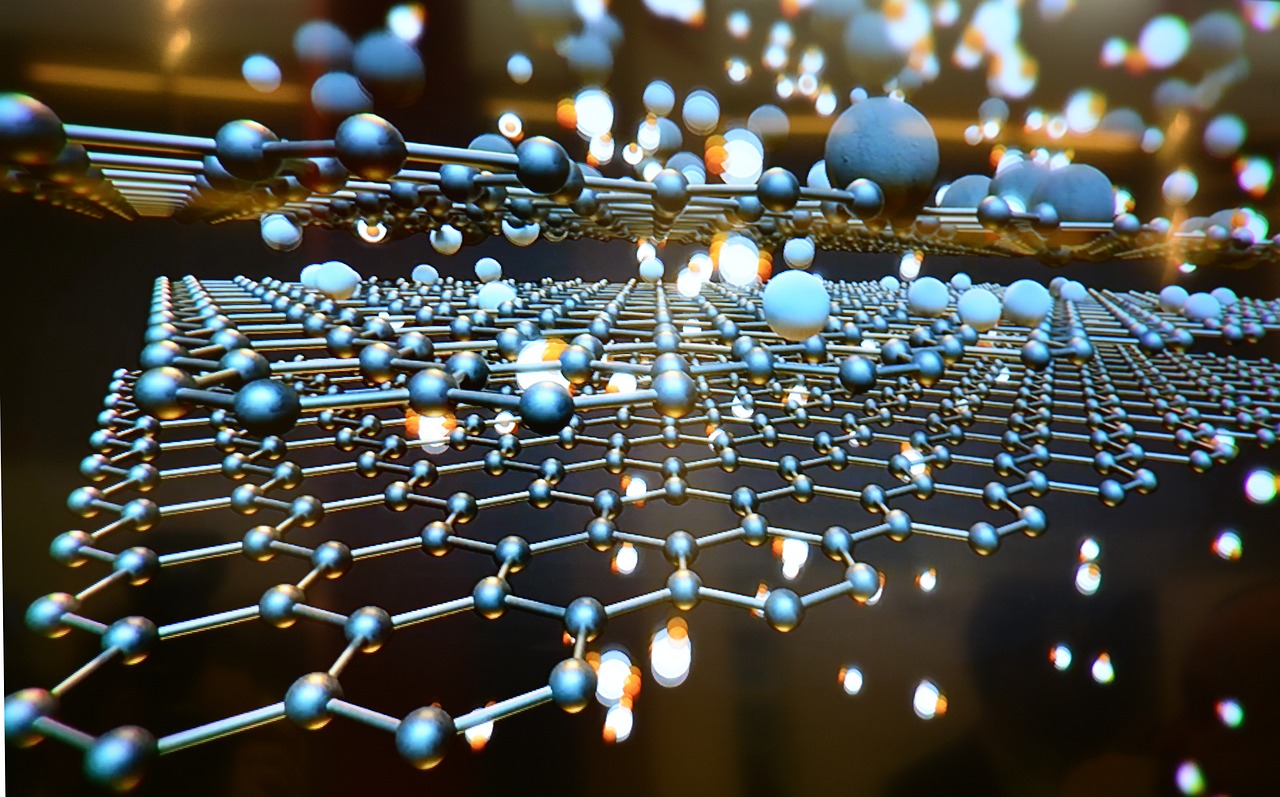

Liquid superlubricity has been demonstrated at the macroscale under ambient conditions with a variety of liquid lubricants with and without additives, for instance, aqueous glycerol with or without nanodiamonds, ionic liquids containing carbon quantum dots or graphene oxide (GO), and ethanediol containing GO, etc. Nevertheless, superlubricity is predominantly observed in specific contact pairs consisting of diamond-like-carbon coatings (DLC) or ceramics, such as steel/ta-C, Si3N4/sapphire and DLC/DLC. However, in self-mated steel contacts, the phenomenon of superlubricity is rarely observed or realized only at low final contact pressures or in a mixed-lubrication regime. Furthermore, in most of research studies, the superlubricity was very susceptible to test parameters, external contaminants, and environmental factors (such as temperature, humidity, etc.). Even a slight alteration to these factors could disrupt the superlubricious layer, resulting in a loss of superlubricity. Therefore, maintaining liquid superlubricity over an extended period under varying operating conditions is necessary for practical applications, especially for steel, the most widely used engineering material in the industrial world.

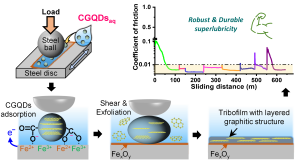

Figure 1: Graphical abstract demonstrating schematic illustration of the superlubricity mechanism of CGQDs-based nanolubricant between steel/steel contact, while the COF versus sliding distance curve demonstrating the robustness and stability of the superlubricity by performing in-situ start-stop tests under various sliding speeds and loading conditions.

Herein, a dedicated intermittent test was designed to show the superlubricity’s robustness and the ability of the tribofilm to adapt to a variety of relevant sliding conditions, which is of great importance for the industrial applications where start-stop operations can cause severe damage and shorten equipment’s service life due to COF fluctuations. Moreover, the boundary film provides an average COF of around 0.007 and up to 69 % wear reduction (compared to the base lubricant), resulting in the maintenance of superlubricity at a real final contact pressure of 123 MPa, which increases the upper limit of the contact pressure compared to current aqueous-lubricated steel contacts. The worn surfaces were analysed using state-of-the-art surface-characterization techniques, including Raman, X-ray photoelectron, and time-of-flight secondary-ion mass spectrometry, while a scanning transmission electron microscope was utilized to investigate the tribo-induced interfacial changes to elucidate the underlying superlubricity mechanism between the steel/steel contacts.

This excellent lubrication effect is due to the synergistic adsorption, shearing and polishing effect provided by the CGQDs dispersed in aqueous glycerol. This research not only sheds light on the active lubrication mechanisms for superlubricity between steel contacts, but also elucidates the role of the physical and chemical structure of CGQDs in achieving superlubricity. The study thus represents an important step in the search for superlubricity in real applications.