Researchers at the Laboratory for Tribology and Interface Nanotechnology (TINT) published a study in Small Strucutres (IF 11.3), in which they explored the functional role of nitrogen-doped graphene quantum dots as additives in environmentally adaptive lubricants to achieve near-zero friction.

Friction and wear are key contributors to energy loss in industry, accounting for over 20% of global energy consumption. Achieving superlubricity—a state of vanishing friction where the friction coefficient falls below 0.01—offers a transformative route to improved energy efficiency, durability, and carbon neutrality. To address this, various lubricants and additives have been explored. However, achieving superlubricity in metallic contact pairs under water-based lubrication, especially at pressures above 200 MPa, remains a major challenge due to issues like severe wear, long running-in times and difficulty maintaining superlubricity over longer period of operation. Graphene quantum dots (GQDs), are considered a miniaturized version of graphene oxide, featuring an advantageous graphene architecture within their dots. Recently, GQDs have become attractive as eco-friendly liquid-lubricant additives owing to their low toxicity, excellent biocompatibility, and small dimensions (<10 nm).

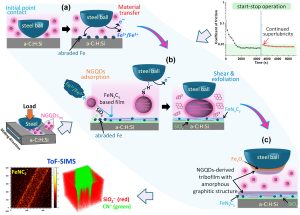

In this work, researchers provide insights into the functional characteristics of nitrogen-doped graphene quantum dots (NGQDs) for achieving superlubricity in aqueous-lubricated systems. Superlubricity was observed in the boundary regime with a friction coefficient of 0.0055–0.0097 between steel and silicon-doped amorphous carbon surfaces under various sliding conditions. Notably, NGQDs reduced wear by 47.8% and enabled a final contact pressure of 206.7 MPa—exceeding previously reported values for aqueous-based superlubricity. Their effectiveness is attributed to enhanced load-bearing capacity via surface adsorption of NGQDs and the tribocatalytic generation of a super-slippery surface film, highlighting their potential for efficient and durable nanolubrication. “The concept of Superlubricity is a highly promising solution for saving energy, reducing environmental impact, and extending the life of mechanical components,” assistant – researcher dr. Irfan Nadeem said. Professor dr. Mitjan Kalin added, “To bring it to industrial scale, we need to study its behaviour under various sliding conditions and uncover new mechanisms that enable it.”

Figure: Graphical abstract illustrating the robustness of superlubricity under start-stop conditions (top right). The upper-left panel presents a schematic of the friction experiment setup. The central section (blue background) highlights the proposed superlubricity mechanism of the nitrogen-doped graphene quantum dot (NGQD)-based nanolubricant. The bottom-left image shows ToF-SIMS analysis revealing the surface chemistry at the sliding interface.