Researchers from the LASIM laboratory (Laboratory for Assembly, Systems, and Pneumatics) conducted a study on the behavior of a hydraulic press in both simulation and physical environments. Utilizing artificial intelligence, they evaluated the adequacy of the simulation model and highlighted key influential parameters for detecting changes in the hydraulic press condition. The research results were published in the Advanced Engineering Informatics journal (IF=8.8).

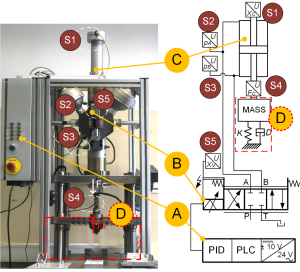

The stability and reliability of hydraulic systems depend on the nonlinear properties of hydraulic components and external environmental influences. Hydraulic presses are often used for forming processes, where the deformation of the specimen generates a force opposing the motion of the hydraulic press, limiting its movement. Frequent operation of the hydraulic press leads to changes in the characteristics of hydraulic components, such as friction conditions in the hydraulic cylinder or guides of the hydraulic press, valve wear, etc., which are the subject of the study. The quantity and quality of sensors determine the ability to capture the necessary information and to detect the response of the hydraulic press under different conditions.

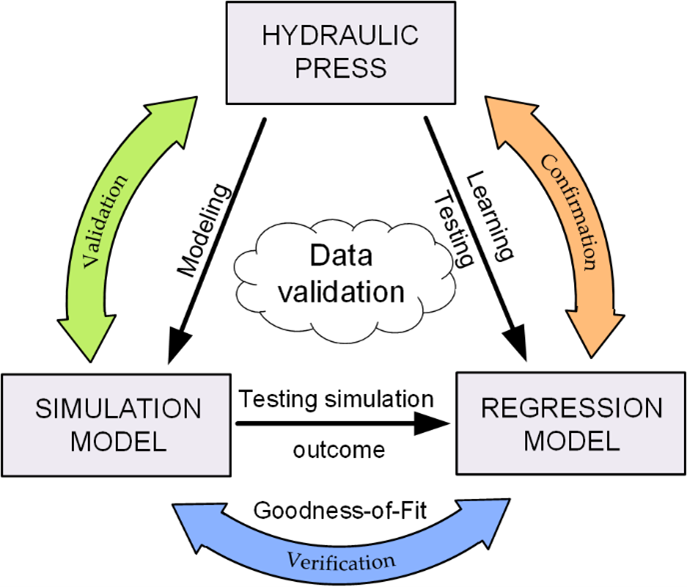

The research demonstrated and confirmed that changes in the operation of the hydraulic press can be detected through experimental, simulation, and regression analyses. The researchers presented a method for data sampling and normalization to extract the most important information. Simulation results are similar to experimental results, showing a consistent trend in the behavior of the hydraulic press in the majority of examined scenarios. The Gaussian regression analysis results highlight shortcomings in the comparative analysis between the virtual and real environments. Correlational similarity of measured parameters is depicted, revealing the identification of specific parameters that play a crucial role in discerning various states of the hydraulic press.

Link to the scientific paper: https://doi.org/10.1016/j.aei.2023.102276