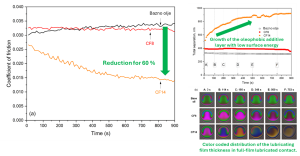

Researchers from the Laboratory for Tribology and Interface Nanotechnology at the Faculty of Mechanical Engineering, University of Ljubljana, have developed a new strategy to reduce friction in highly loaded contacts with a full lubricating film. The key outcome of the research is the first proof-of-concept showing that the use of fluorinated carboxylic acids as oil additives can reduce friction by as much as 60%—and already at ambient temperature—which has so far been considered a major challenge. The breakthrough results were published in the journal Tribology International (Impact Factor = 6.9).

Reducing friction is important as it improves energy efficiency and extends the lifespan of machine elements such as bearings and gears, which are found in nearly all moving parts of machines and vehicles. In the past, smaller friction-reducing effects were achieved using additives, but only at elevated temperatures. This study is the first to show that friction can be reduced much more significantly—and already at ambient temperature.

The research builds upon the lab’s previously developed concept of using oil additives to reduce friction in the full-film lubrication regime, opening an entirely new field of additive application, as additives have almost exclusively been used only in boundary lubrication regimes. Adding these additives to oil is a simple, significantly cheaper, and more effective solution for reducing friction than applying functional surface coatings, which have until now been considered the most effective solution for friction reduction in full-film contacts.

The study showed that the key factor influencing friction reduction is the molecular chain length of the additives and their ability to form a homogeneous, densely packed oleophobic layer with low surface energy. The most effective molecule was found to be a fluorinated carboxylic acid with a 16-carbon atom chain.

In addition to basic friction measurements, the researchers also carried out several surface analyses (FTIR, SEM, interferometry), which clearly confirmed the formation and persistence of the functional lubricating layer. Interestingly, a thicker layer does not necessarily lead to a better effect—uniform surface coverage and chemical composition proved to be more important.

The study provides a new understanding of how the molecular design of additives can directly affect friction even under full-film lubrication conditions (in which machine elements operate most of the time), without the need for special coatings or high temperatures typically required to activate additives. This opens new opportunities for using such additives in industry, where more sustainable and efficient solutions are being sought. The article has been published in the journal Tribology International.