Researchers at the Laboratory for Water and Turbine Machines (LVTS) have conducted an experimental study in the field of acoustic cavitation, the main objective of which was to determine a new acoustic cavitation number. The results of the study are published in the prestigious journal Ultrasonics Sonochemistry (IF: 9.336).

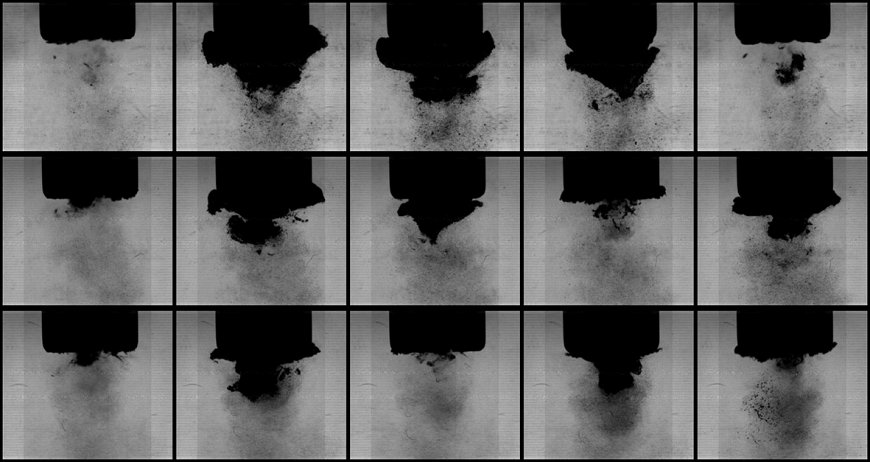

Figure 1: Typical case of a cavitation under 20 kHz ultrasonic horn tip 4.8 mm in diameter.

As a physical phenomenon, cavitation is the result of a sudden, localized drop in pressure in a fluid and manifests itself in the formation of small vapor bubbles that, when they collapse, can cause a number of problems. Cavitation most commonly occurs in hydraulic machines, such as water turbines or various constrictions (such as fuel injectors in internal combustion engines) and valves. The presence of cavitation can cause a drop in the performance of the machine or device, noise, vibration and, what engineers fear most, so-called cavitation erosion, i.e., damage to the material. Basically, cavitation can be divided into hydrodynamic cavitation, which occurs in the flow of a liquid through a submerged body, and acoustic cavitation, which is the result of acoustic waves traveling through the liquid. Nowadays cavitation is also used in various fields, e.g. in medicine, for cleaning surfaces, in the treatment of drinking or waste water, etc.

In the field of hydrodynamic cavitation, the so-called cavitation number has been used for many decades, which can be used to roughly describe the occurrence and magnitude of the cavitation that occurs. Despite some drawbacks, the cavitation number is often used mainly for relative comparison of cavitation conditions in two-phase flows. It can be used to predict the probability of occurrence of cavitation and the degree of development of the phenomenon under certain flow conditions, which is particularly important in engineering practice.

In the field of acoustic cavitation, there is as yet no similar parameter describing the cavitation condition. The use of ultrasonic sonotrodes or homogenizers is widespread in the fields of biology, chemistry, pharmacy and environmental protection, but still the physical phenomena present have not been fully explored.

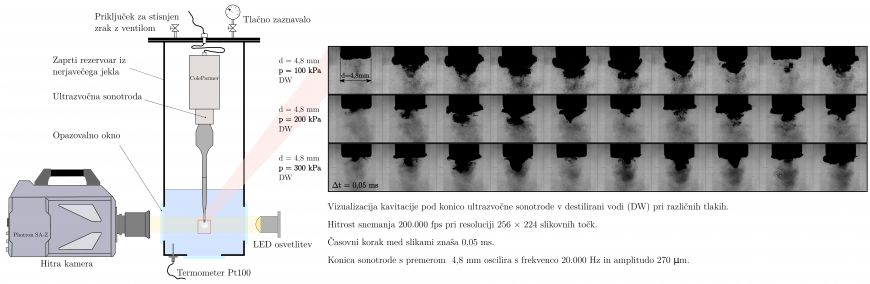

Using a parametric study in which the researchers systematically changed the ambient pressure, the diameter and immersion of the tip, the amplitude of tip movement, and the properties of the liquid, they derived an empirical equation that can be used to roughly predict the cavitation state under the sonotrode tip. With the help of the results published in the aforementioned journal, they thus added a piece of knowledge to the mosaic that other researchers can use in the future for both further basic research and applied studies.

Figure 2: Experimental setup (left) with image sequences from high-speed visualization under various operating conditions (right).

Link to the scientific paper: https://doi.org/10.1016/j.ultsonch.2022.106159.