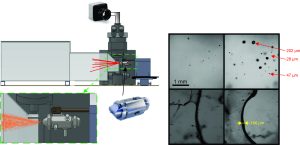

Liquid atomization plays an important role in different industrial applications and also in the manufacturing of the pharmaceutical products. In some productions steps, including fluid bed granulation and film coating, precise atomization of liquids is essential for optimal results. Observation of fast droplets and ligaments on the micron scale generally requires complex experimental equipment with pulsed illumination and traceable particles, which limit the comparison of experimental results with real environment conditions. To overcome the limitations of current techniques, the research team from Laboratory for Thermal Technology (University of Ljubljana, Faculty of Mechanical Engineering) and Krka, d.d., Novo mesto developed innovative method to determine spray droplet speed and size distributions as well as to analyze liquid ligament breakup process.

Study was conducted with water and three different hypromellose (HPMC) polymer dispersions, which proved the applicability of developed method in relatively wide range of droplet sizes (49–413 μm) and speeds (10–46 m/s). It was also shown that the shape of cumulative volumetric droplet size distribution can be used to evaluate the successfulness of ligament breakup (i.e., formation of droplets) and by that the spray quality. Due to the simplicity of proposed method and data processing, the entire system is potentially suitable for near real-time coating monitoring and for rapid optimization of the atomization process.

Scientific paper is published in International Journal of Pharmaceutics (IF = 6,51) and is freely accessible through the link: https://doi.org/10.1016/j.ijpharm.2022.122412