Researchers from the Laboratory for Forming (LAP), in collaboration with the Faculty of Engineering at the University of Rijeka, Croatia, have published the results of their research in the prestigious Elsevier’s journal Applied Soft Computing (IF=8.263). The study focused on single-point incremental forming (SPIF), which allows sheet metal to be formed using a relatively small, geometrically simple tool whose trajectory determines the shape of the final product. Formability is determined by excessive thinning of the sheet, which leads to fracture. This characteristic of the forming process can be improved by developing the basic SPIF process into a two-step forming process consisting of sequential execution of bulging and SPIF. With this approach, a more uniform distribution of the sheet thickness can be achieved.

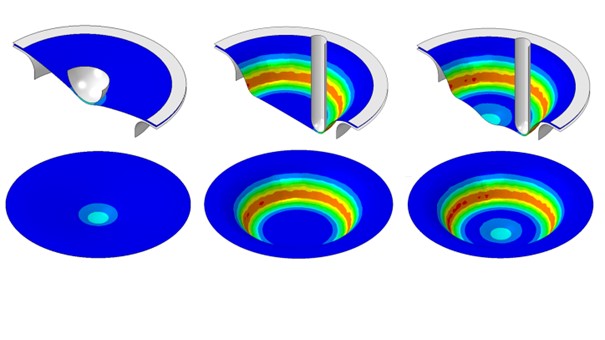

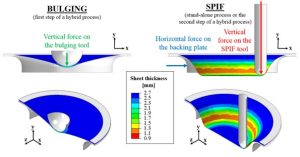

Figure 1. Comparison of bulging and SPIF in the ABAQUS simulation environment. Shown are the output parameters of the sheet metal thinning and forming force components.

Two key output parameters on which the analysis focused were the sheet metal thinning and maximum forming force components. To this end, simulations of both SPIF forming and hybrid two-step forming, consisting of sequential execution of bulging and SPIF, were performed in the ABAQUS simulation environment. The random forest method (RF) was used to analyse the influence and correlation between a large number of technological, material and geometrical input parameters of the two mentioned forming processes. The RF method allowed the determination of the influence of individual parameters by analysing tree-shaped models obtained through the training process.

The analysis results show a significant influence of the workpiece wall angle and the workpiece depth on the sheet metal thinning. It is also clear that the initial sheet thickness affects the values of the forming force components. The results also show a large correlation between the parameters of the bulge depth and the part depth after SPIF.

Link to the article: https://doi.org/10.1016/j.asoc.2023.110497