Researchers from the Laboratory for Pumps, Compressors and Technical Acoustics, in collaboration with researchers from Universidade de Coimbra, have presented the concept and process of parametric optimization of liquid piston compressors. Their work was published in the journal Applied Thermal Engineering (IF=6,4).

The advantages of the liquid piston compressor, such as the near isothermal compression, the absence of friction of metal parts and internal leakage, and the possibility of adapting the geometry to the compressed fluid, are favourable features for the use of this type of compressor for the efficient compression of media and for energy storage.

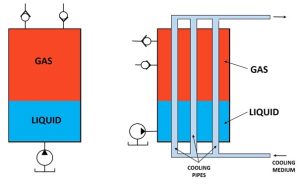

The research is focused on the study of the implementation of the compressor with inserted cooling tubes, which additionally contribute to a near isothermal compression.

Left: convential liquid piston compressor, right: liquid piston with inserted cooling tubes

A method of optimizing the aforementioned device was presented, in which the efficiency is influenced by a variety of parameters, such as the length and thickness of the cooling tubes, their number, shape and distribution in the compression chamber. Also, a correction of the calculation of the heat transfer coefficient on the inner surfaces of the compression chamber was proposed.

The presented concept of the liquid piston compressor enables efficient and environmentally friendly energy conversion and storage in a wide range of applications in industry, energy and transport.

You can read the article on the website: https://doi.org/10.1016/j.applthermaleng.2023.120436