By utilizing infrared thermography, researchers from the LTT laboratory (Laboratory for Thermal Technology) were the first to show spatial and temporal changes in plate heat exchanger performance during salt crystallization. The results of the study were published in the journal Applied Thermal Engineering (IF = 6.465).

Fouling due to inversely soluble salt crystallization is common in practical heat exchanger operation and can drastically impact heat transfer performance and hydraulic conditions inside the equipment. In order to study and successfully mitigate this phenomenon, local observation of events is highly desirable, but remains challenging in compact equipment without altering the geometry.

In the presented research, the authors have successfully shown a novel application of infrared thermography to calcium carbonate fouling evaluation in a plate heat exchanger, allowing for real time monitoring of performance with high spatial and temporal resolution and with minor changes to the studied equipment. The described approach is scalable to all plate heat exchanger geometries and orientations, allowing the location of areas more susceptible to deposition and blockage.

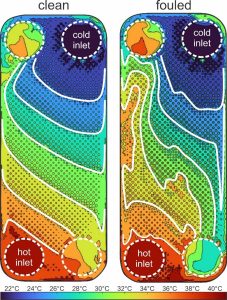

Comparison of plate heat exchanger temperature distribution before and after crystallization.

The results confirm that such areas are closely related to flow stagnation zones inside the plate heat exchanger, wherein the formation of large deposits drastically changes flow distribution, which together with the added deposit thermal resistance severely reduces heat transfer performance.

Link to the article: https://doi.org/10.1016/j.applthermaleng.2023.120116.